Vedum Kök & Bad, a Swedish manufacturer of kitchens and bathrooms, recently expanded with a new 11,000 square-meter warehouse to increase capacity and improve logistics.

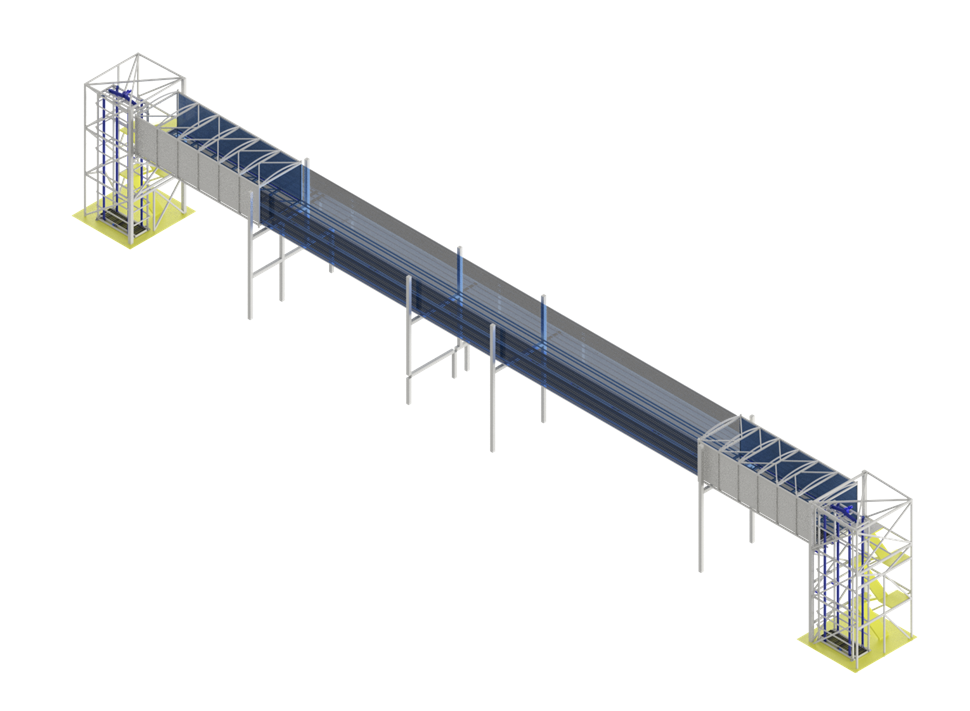

A railway line between the old and new facilities posed a logistical challenge. To ensure smooth material flow, Q-System delivered an 80-meter conveyor system integrated into a bridge connecting the two buildings.

How the system works

The automated transport solution includes:

- Lifts: Raising pallets 10.5 meters up to the bridge and lowering them on the other side.

- Conveyors: Moving pallets efficiently across the enclosed bridge.

- Barcode scanning: Directing pallets to the right destination.

Increased efficiency and safety

With space freed up for expanded production, Vedum Kök & Bad is set for growth in the next decade. The automated system minimizes manual handling and forklift use, improving both efficiency and workplace safety.

By delivering a tailored conveyor solution, Q-System has helped Vedum Kök & Bad streamline logistics and maximize productivity.

Machines used in this case:

- Heavy conveyors

- Lift systems

- Chain driven conveyors