Haldex Brake Products is a leader in providing advanced brake systems for heavy vehicles, focusing on improving road safety and vehicle performance.

In 2018, Q-System delivered a comprehensive automation solution to Haldex Brake Products in Landskrona, Sweden. The goal was to support Haldex in bringing their previously outsourced painting process in-house and streamline the internal flow.

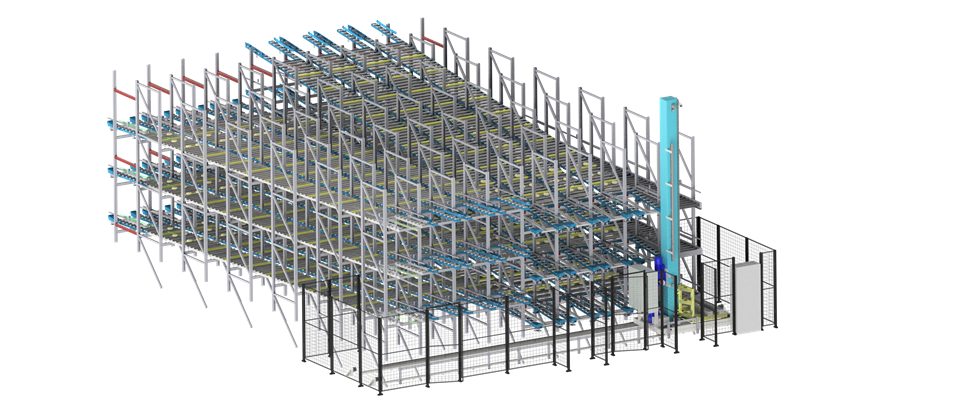

Key Components of the Solution

- Multi-level buffer system

9 lanes across, 3 levels high – with a total capacity of up to 324 pallets - Robotic cell

3 industrial robots handle picking of parts from a powered in-feed roller conveyor - Automated pallet transport

Integrated AGV (Automated Guided Vehicle) and a Q-Loader move pallets between buffer zones and the painting cell

System Functionality

To support the new automated painting line, the solution had to:

- Handle heavy pallets

- Provide efficient buffering of both unpainted and painted parts

- Minimize manual handling to improve both productivity and ergonomics

We delivered a custom medium conveyor system featuring:

- 15 in-feed gravity roller conveyors

Holds up to 180 pallets with unpainted parts - 12 out-feed conveyors

Holds up to 144 pallets with painted parts

Controlled and Safe Pallet Handling

To ensure smooth and safe pallet flow:

- Brake rollers were installed to prevent uncontrolled pallet movement

- Separation stops were added to allow controlled release of pallets for collection

Results for Haldex Brake Products

- Manual pallet handling eliminated

- Improved efficiency and safer working conditions

- Full integration with the automated painting line

This tailored automation setup has helped Haldex increase throughput and reduce physical strain on workers – while maintaining full control of internal logistics.

Machines used in this case:

- Driven converyor rollers

- Non-driven conveyor rollers

- Brake rollers

- Q-loader

- AGV

- Storage systems

- Robot cells