Q-system delivered a complete system for Prime Cargo back in 2014. Since then DSV has bought Prime Cargo.

Prime Cargo, headquartered in Kolding, expanded its operations by establishing a new 10,000 m² 3PL center in Goleniow, Poland. The facility was designed to handle storage, packing, and distribution for customers across Scandinavia and Europe, with a focus on improving efficiency and capacity through optimized material handling solutions.

Key benefits:

- Minimized manual handling, reducing operator workload and improving efficiency.

- A modular setup to support future scalability.

- Enhanced workflow between manual processes, ensuring a smooth transition across operational stages.

What we delivered:

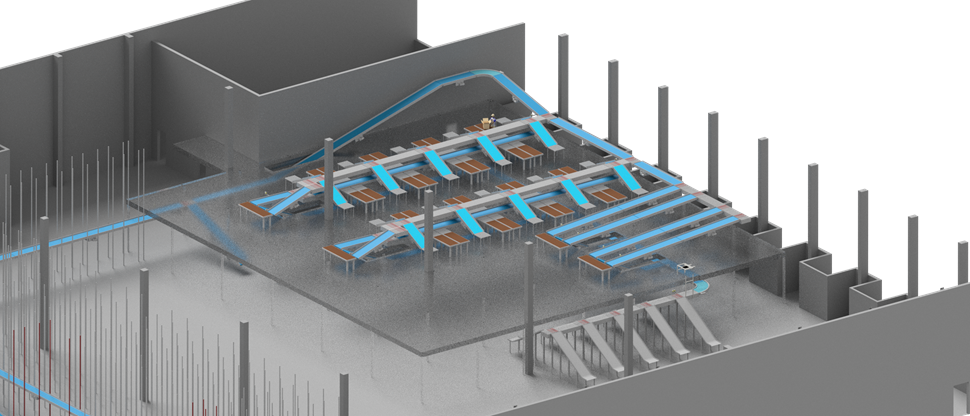

Q-System delivered a tailored conveyor system to streamline operations at the facility. The system includes:

- Roller conveyors, inclined and declined belt conveyors, and chutes across two levels, integrating processes from picking and packing to sorting.

- A mezzanine level where individual packing is handled, connected to other operational levels for seamless material flow.

By automating key processes, the system reduces manual steps, improves efficiency, and increases capacity. Currently, it handles up to 25,000 boxes per day, with plans to expand capacity to 50,000 boxes per day as part of a second-phase upgrade.

Machines used in this case:

- Belt conveyors

- Light conveyor solutions