PASCHAL Denmark needed an automated conveyor system to streamline the cleaning and sorting of their rented formwork elements.

Our Solution

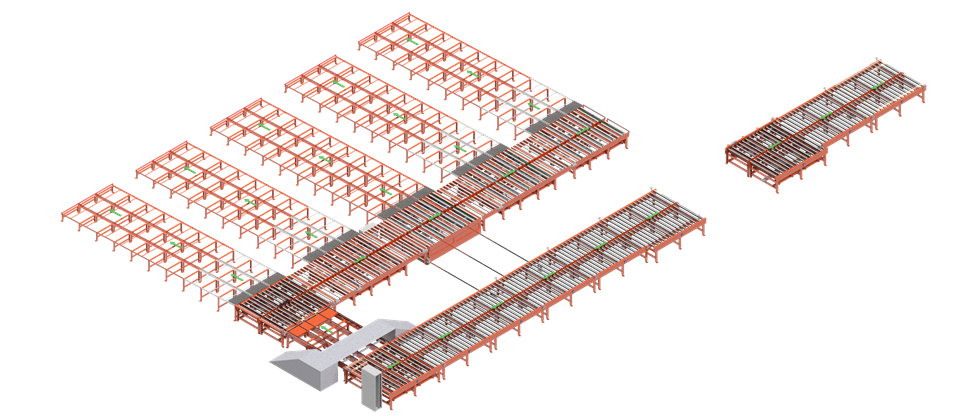

Q-System designed and delivered a conveyor system tailored to PASCHAL's requirements. Key components included:

- Powered roller conveyors with angle transfers for smooth and precise movement of formwork elements.

- A cleaning machine integrated into the system to handle the removal of dirt and debris.

- Gravity conveyors for efficient outfeed and stacking.

- A custom transfer cart for repairing larger elements directly on the line.

Machines used in this case:

- Driven roller conveyors

- Chain conveyors