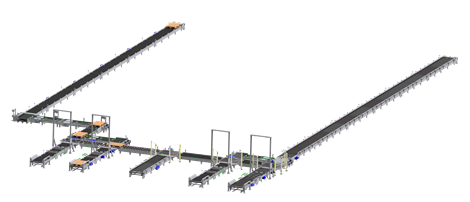

Optimizing inbound and outbound logistics with automated solutions

Efficient pallet handling

At Frigoscandia’s new cold storage facility, efficient material handling plays a key role in keeping operations smooth and products at peak quality. To support this, Q-System has delivered conveyor-based automation that reduces manual work, improves tracking accuracy, and ensures reliable pallet flow in and out of the facility.

What Q-System delivered:

- Automated conveyor systems for both inbound and outbound pallet handling

- Integrated pallet inspection to check incoming goods against quality standards

- Turntables for label alignment, ensuring labels are always visible for scanning

- Seamless flow control, minimizing manual interventions and bottlenecks

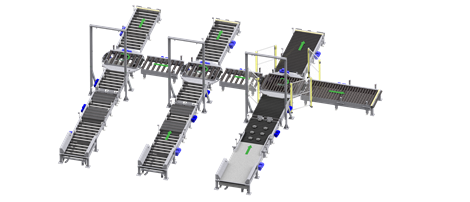

Inbound: Quality check and label alignment

- Pallets pass through an automated inspection zone, where both pallet and goods are checked

- A turntable rotates the pallet, aligning the label correctly for scanning

- This ensures traceability and compliance before goods enter storage

Outbound: Shipment preparation made easy

- Pallets are automatically routed to shipping via conveyor

- Before leaving the facility, each pallet is rotated again, so the label faces outward

- This setup ensures quick and efficient scanning at the next destination

The result for Frigoscandia:

- Increased logistics efficiency: smoother pallet flow in both directions

- Improved quality control: thanks to consistent inspection and label orientation

- Reduced manual handling: minimizing strain and labor in a cold environment

- Reliable operations: automation ensures consistent performance, even under demanding conditions

Machines used in this case:

- Heavy conveyor systems

- Turntable

- Pallet control