At their facility in Vejle, Lantmännen Cerealia manages the packing and distribution of flour and oat bags.

To streamline their processes and meet growing demands, they turned to Q-System for a fully automated solution.

What we delivered:

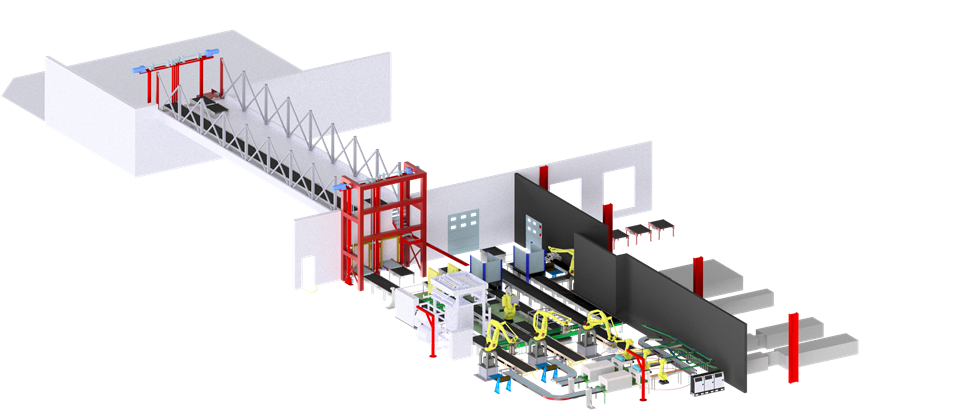

The installation includes a tailored system of standard and custom conveyor modules paired with eight robotic cells. These handle every step of the process: from single bags arriving at the line to fully stacked pallets ready for transport.

The pallets are efficiently transported via elevators, bridges, and transfer cars to ensure smooth operations. Empty pallets are automatically returned to the production area through a closed-loop system, guaranteeing continuous workflow without interruptions.

Benefits for Lantmännen Cerealia:

This automated setup allows for faster, more precise handling of products, minimizes the need for manual labor, and enhances workplace safety. With improved logistics, Lantmännen Cerealia has optimized their production flow, enabling them to deliver high-quality products to customers efficiently and reliably.

Machines used in this case:

- Driven roller conveyors

- In-line pallet magazine

- Lifts

- Robot cells from Gibotech

- Transfer carts