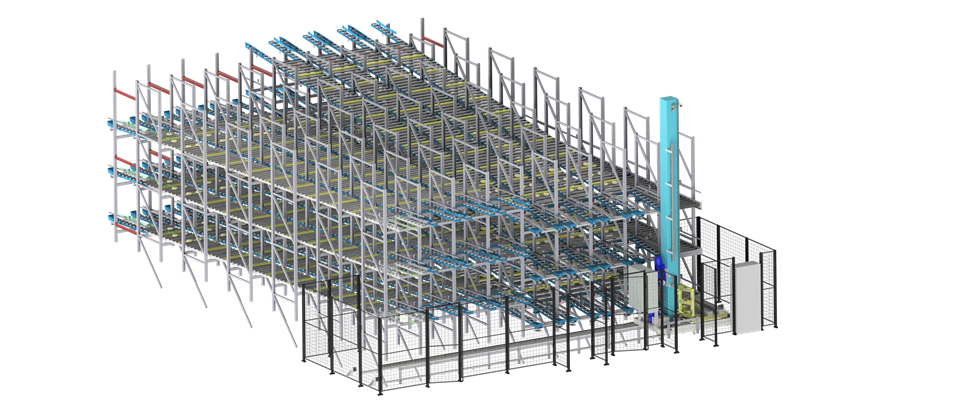

Optimized manufacturing with automated material handling

Our customizable solutions, from roller conveyors to integrated transport systems, ensure seamless material flow, enhancing productivity and reducing bottlenecks in your production processes.

Implementing automated transport systems improves efficiency, reduces manual labor, and ensures a smooth workflow across all production stages.

- Faster production: Minimizes delays and keeps operations running

- Reduced manual handling: Lowers strain and injury risks

- Consistent quality: Ensures stable and precise movement of materials

- Cost-efficient: Cuts labor costs and optimizes resource use

- Flexible and scalable: Adapts to production changes and growth

We have solid experience in building efficient production lines where materials move reliably from one stage to the next. Our solutions are developed to support daily operations and make it easier to adjust when production needs change.

Smart Material Handling for Manufacturing Performance

Optimized material flow is essential for efficient manufacturing and seamless logistics. Q-System’s automated transport solutions, including roller conveyors and integrated handling systems, ensure a steady and controlled movement of materials throughout production. By reducing manual handling and minimizing downtime, our solutions improve productivity and enhance workplace safety. With scalable and flexible systems, manufacturers can adapt to changing demands while maintaining consistent quality and cost efficiency. Whether streamlining assembly lines, automating material transport, or improving warehouse logistics, Q-System provides reliable solutions that optimize manufacturing operations.

Enhancing furniture manufacturing with conveyor and robotics solutions

In the furniture industry, managing heavy materials and components efficiently is essential for maintaining productivity and safety. Conveyors offer a practical solution by facilitating the smooth movement of large furniture pieces and raw materials throughout the production line. By reducing manual handling and minimizing the risk of injury, roller conveyors enhance workplace safety while accelerating production processes.

Q-System's conveyor solutions are designed to accommodate the unique challenges of furniture manufacturing. Our systems integrate seamlessly with automated mobile robots (AMRs) and robotic arms, enabling intelligent material handling and optimized workflows. AMRs can transport components between workstations, while robotic systems handle lifting, positioning, and assembly with precision. This synergy between conveyors and automation not only boosts productivity but also ensures greater flexibility, consistency, and quality throughout your manufacturing operations.