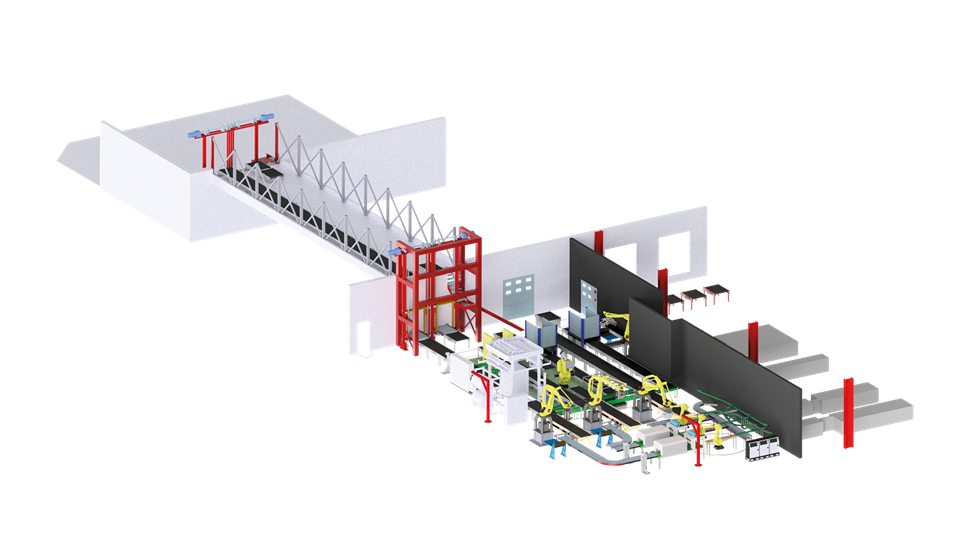

Optimized Intralogistics for Automated Workflows

Seamless material flow is key to maximizing efficiency in automated production. With us as your intralogistics partner, you get solutions that connect conveyors, robots, AMRs, and AGVs into one cohesive system, ensuring smooth and reliable operations.

Integrated Automation for Smarter Material Handling

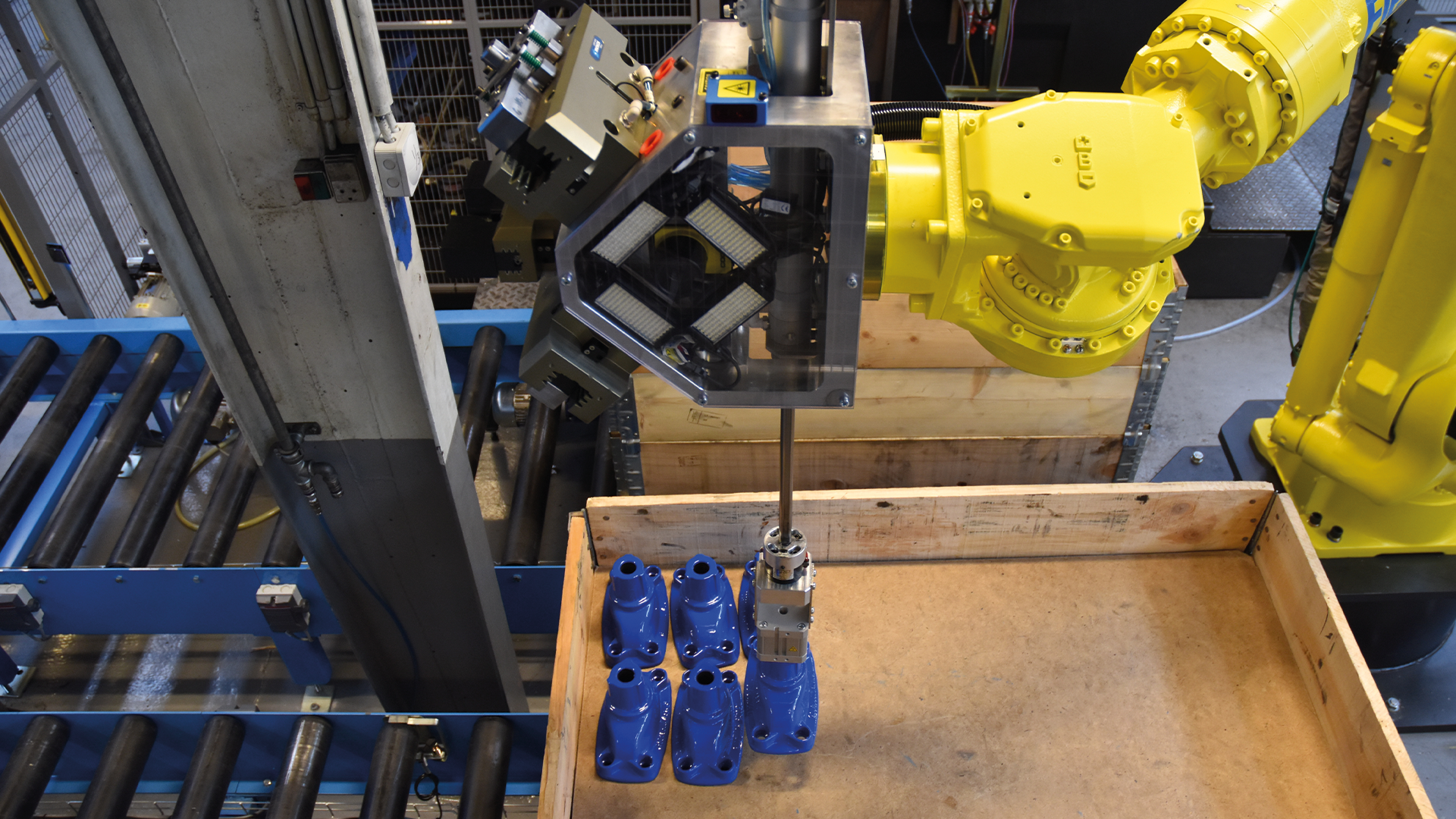

Our material handling solutions are designed to support large-scale automation by integrating with robotic arms, autonomous mobile robots (AMRs), and automated guided vehicles (AGVs). By working as a connected system, these technologies ensure a continuous and optimized production flow.

- Seamless integration: Our solutions connect conveyors with robots, AMRs, and AGVs, ensuring automated material handling without interruptions.

- Optimized efficiency: Automated transport of goods between workstations reduces manual handling and eliminates bottlenecks.

- Scalable and adaptable: Modular systems adjust to different layouts, load capacities, and automation needs.

- Reliable performance: Durable and low-maintenance designs ensure continuous operation and minimal downtime.

By combining automation technologies into a single, efficient system, we help businesses streamline operations, improve productivity, and create smarter material handling workflows.

Future Proofing Your Automation Strategy

As industries increasingly rely on automation, the need for smart, interconnected systems becomes essential. Our solutions enable businesses to enhance material flow, reduce reliance on manual labor, and create a scalable infrastructure that grows with production demands. Whether integrating with robotic picking systems, coordinating AMRs for warehouse transport, or synchronizing AGVs with conveyor networks, we ensure that every component works in harmony.By leveraging automation in intralogistics, companies can achieve greater accuracy, faster processing times, and improved cost efficiency, ultimately strengthening the bottom line.